ER-6000 AT

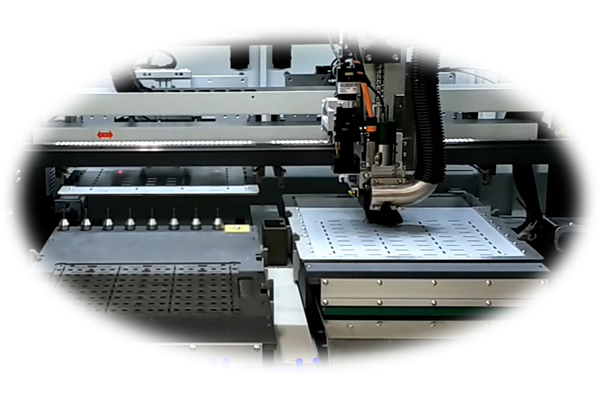

IN LINE PCB Separator Cut Machine

Specification

- Sliding table positioning mode: Servo precise positioning double sliding table

- Pick-and-place method: single-head pick-and-place mechanism

- Cover mode: magnet buckle platen mechanism

- Maximum working range of upper dust collection(W*D)900x630mm

- Maximum working range of lower dust collection(W*D)900x650mm

- SS, SL, SX, S70L, S80L and S90L can only be used as single slides

- Working height:920mm±20mm

- Cutting speed:1~100 mm/s

- Mechanical repeatability:± 0.01 mm

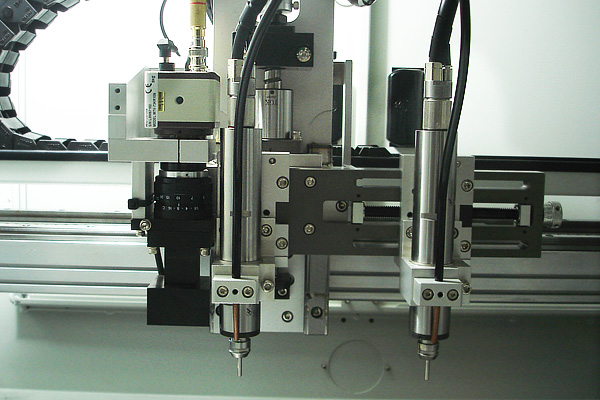

- Control System:PC-based 6 Axis controller

- Drive way:AC Servo motor

- working system:IPC Windows 10

- Cutting accuracy:± 0.05 mm

- Spindle speed:Max. 60000 rpm

- Host voltage:1φ, AC 220V 50/60Hz

- Air supply:4~6 kg/cm², flow:1500 L/hr

- Power consumption:3.0 KVA

- Dust collection method:External type,upper exhaust type 3HP,See Catalog EV-720

- Dust collection method:standard External type,lower exhaust type 3HP,See Catalog 3(5)HP

- Front station conveyor belt height: 920 ± 20 mm

- Rear station conveying mode: belt type, rail type, carrier type,ES-602 can be selected according to customer needs

- Flow direction: left to right, right to left

- Static elimination:Static elimination gun (lower exhaust type)

PCB transport mechanism

Auto loading and unloading(Modular vaccum nozzle, independent vaccum sensor)

P&P Device

lateral movement/up/down to be AC servo motor control

P&P Speed

Max.500mm/sec

Conveyor width

Min. 80 mm

- Equipped with automatic replacement of milling cutter function.

- Gantry structure increase cutting acuracy and cutting speed

- With 0 ~ 5 times automatic lower stage compensation, it extends the service life of the milling cutter and reduces the cost.

- Integrated shell and safety door sensor fit for public safety demand

- Using working table to push PCB panel margin into trash bucket which is in front of router to reduce equipment placement space

- Off-line module dedicated fixture with vacuum pick up nozzles decreasing change production line

| Type | Workbench | Up suction working range (W*D) |

Down suction working range (W*D) |

Customer fixture restrictions (W*D) |

| AT_DS | 2 Table | 250*320mm | 250*340mm | 294x350mm |

| AT_DW | 2 Table | 330*320mm | 330*340mm | 370x350mm |

| AT_DWL | 2 Table | 330*620mm | 330*640mm | 370x650mm |

| AT_DM | 2 Table | 400*420mm | 400*420mm | 440x450mm |

| AT_DX | 2 Table | 500*470mm | 500*490mm | 540x500mm |

| AT_DXL | 2 Table | 500*620mm | 500*640mm | 540x650mm |

| AT_DXXL | 2 Table | 600*620mm | 600*640mm | 650x650mm |

| AT_D65L | 2 Table | 650*620mm | 650*640mm | 700x650mm |

| AT_S70L | 1 Table | 700x630mm | 700x650mm | 750x660mm |

| AT_S80L | 1 Table | 800x630mm | 800x650mm | 850x660mm |

| AT_S90L | 1 Table | 900x630mm | 900x650mm | 950x660mm |

| Type | weight(Kg) | Machine size W*D*H | Picture file | |

| AT_DS | 770 | 2000*1340*1980mm | The scope of work | |

| AT_DW | 950 | 2100*1340*1980mm | The scope of work | |

| AT_DWL | 1020 | 2100*1740*1980mm | The scope of work | |

| AT_DM | 1010 | 2450*1420*1980mm | The scope of work | |

| AT_DX | 1150 | 2950*1530*1980mm | The scope of work | |

| AT_DXL | 1300 | 2950*1740*1980mm | The scope of work | |

| AT_DXXL | 1450 | 3450*1740*1980mm | The scope of work | |

| AT_D65L | 1600 | 3700*1740*1980mm | The scope of work | |

| AT_S70L | 1400 | 3100*1750*1980mm | The scope of work | |

| AT_S80L | 1500 | 3400*1850*1980mm | The scope of work | |

| AT_S90L | 1600 | 3700*1850*1980mm | The scope of work |