ER-8000 AT

IN LINE PCB Separator Cut Machine

Specification

- Sliding table positioning mode: Servo precise positioning double sliding table

- Pick-and-place method: single-head pick-and-place mechanism

- Cover plate method: cylinder type platen mechanism

- Maximum working range of upper dust collection(W*D)400x320mm

- Maximum working range of lower dust collection(W*D)400x340mm

- Working height:920mm±20mm

- Cutting speed:1~100 mm/s

- Mechanical repeatability:± 0.01 mm

- Control System:PC-based 6 Axis controller

- Drive way:AC Servo motor

- working system:IPC Windows 10

- Cutting accuracy:± 0.05 mm

- Spindle speed:Max. 60000 rpm

- Host voltage:1φ, AC 220V 50/60Hz

- Air supply:4~6 kg/cm², flow:1500 L/hr

- Power consumption:3.0 KVA

- Dust collection method:External type,upper exhaust type 3HP,See Catalog EV-720

- Dust collection method:standard External type,lower exhaust type 3HP,See Catalog 3(5)HP

- Static elimination:Static elimination gun (lower exhaust type)

- Front station conveyor belt height: 920 ± 20 mm

- Rear station conveying mode: belt type, rail type, carrier type,ES-602 can be selected according to customer needs

- Flow direction: left to right, right to left

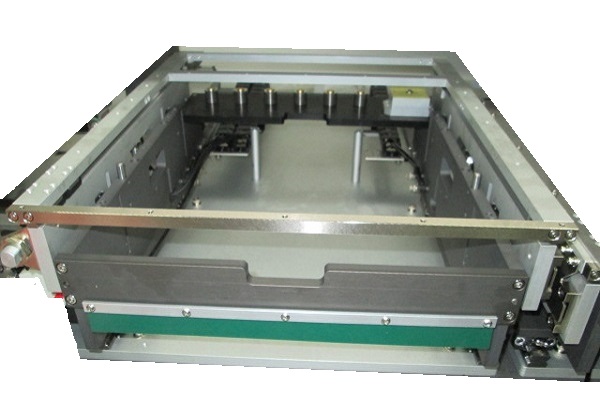

PCB transport mechanism

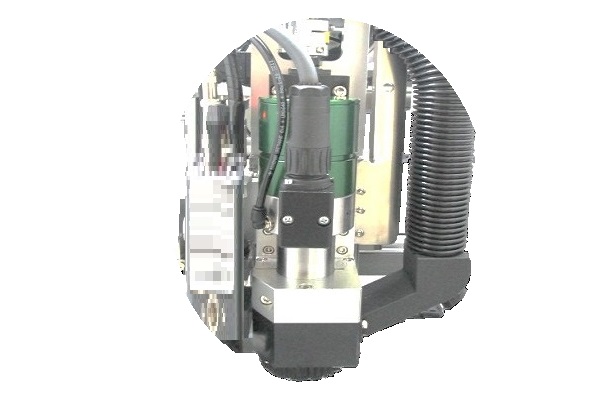

Auto loading and unloading(Modular vaccum nozzle, independent vaccum sensor)

Pick and place device

Automatic loading and unloading (modularized vacuum claw, vacuum detection device, can be selected independently)

P&P Device

lateral movement/up/down to be AC servo motor control

P&P Speed

Max.500mm/sec

Conveyor width

Min. 80 mm

- Equipped with automatic replacement of milling cutter function.

- Gantry structure increase cutting acuracy and cutting speed

- Extended router bit's life by multistage auto compensation of Z height to reduce cost

- Integrated shell and safety door sensor fit for public safety demand

- Using working table to push PCB panel margin into trash bucket which is in front of router to reduce equipment placement space

- Off-line module dedicated fixture with vacuum pick up nozzles decreasing change production line

| Type | Workbench | Up suction working range (W*D) |

Down suction working range (W*D) |

Customer fixture restrictions (W*D) |

| AT_DW | 2 Table | 330x340mm | 330x340mm | 370x350mm |

| AT_DWM | 2 Table | 400x340mm | 400x340mm | 440x350mm |

| 型號 | weight(Kg) | Machine size W*D*H | Picture file | |

| AT_DW | 930 | 2260*1340*2010mm | The scope of work | |

| AT_DWM | 1000 | 2610*1340*2010mm | The scope of work |